BS 10 TABELLA D FLANG

Standard Brittaniku BS 10: 1962 - Speċifikazzjoni għall-Flanges u Bolting għal Pajpijiet, Valvoli, u Fittings.Dan ikopri flanġijiet sempliċi, boxxla, mitfugħa integralment jew falsifikati, u flanġijiet tat-tip tal-għonq tal-welding, f'għaxar tabelli.Għalkemm BS 10 huwa skadut, jibqa 'jintuża għad-dimensjonijiet ta' dazju ħafif, flanġijiet tal-istainless steel ekonomija f'applikazzjonijiet fejn ir-reżistenza għall-korrużjoni u/jew l-iġjene, aktar milli pressjonijiet u temperaturi għoljin, huma l-konsiderazzjonijiet primarji.It-tabelli li ġejjin jagħtu dettalji dwar id-dimensjonijiet standard applikabbli mit-Tabelli D, E, F u H tal-BS 10.

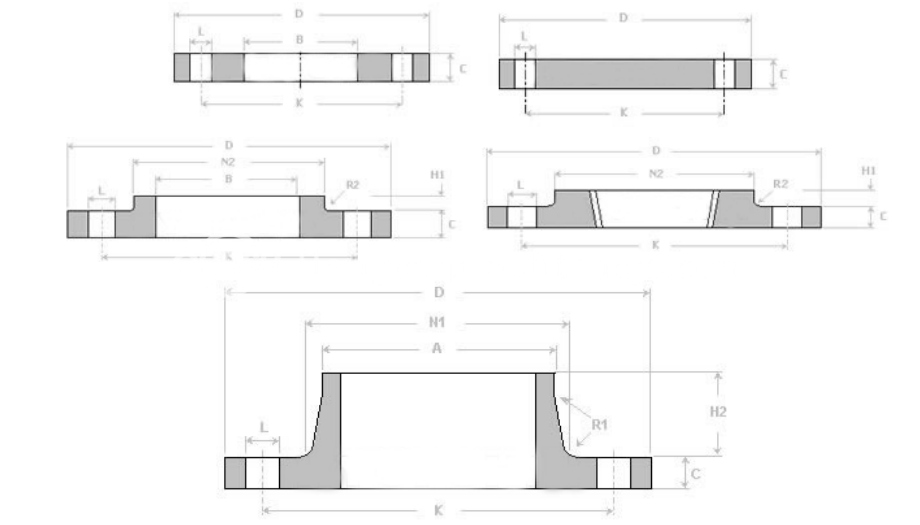

Dimensjonijiet tal-ħanek u Mases approssimattivi

| BRITANNIKA BS 10 SPEĊIFIKAZZJONI TAL-FLANGE TABLE D | ||||||||||||||

| DAQS NB | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | TOQOB | |

| IN | mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 4.8 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 4.8 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 4.8 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1 ¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 6.4 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 6.4 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 7.9 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 7.9 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 9.7 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 9.7 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 9.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 12.7 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 12.7 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 12.7 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 16.0 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 19.1 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 22.2 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 22.2 | - | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 25.4 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 28.6 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 31.8 | - | - | 616.0 | - | - | - | - | 16 |

Kapaċità tal-Produzzjoni u Dettalji tax-Xiri.

1.Dimensjoni tal-Fanġ tal-Provvista DN15 - DN2000 (1/2″ - 80″), Flanġ Falsifikat.

2.Azzar tal-Karbonju Materjal: ASTM A105, S235JR, C22.8, RST37.2, ST37, P245GH, P250GH, ASTM A181, Q235

3.Materjal Stainless Steel: ASTM A182 F304, F304L, F316, F316L, F321 eċċ.

4.Flanges Kontra s-sadid: Żejt kontra s-sadid, Żebgħa Iswed, Kisi ta 'Żebgħa Isfar, Galvanizzat Hot Dipped, Galvanizzat kiesaħ eċċ.

Output 5.Monthly: 3000 tunnellata kull Xahar.

Termini 6.Delivery: CIF, CFR, FOB, EXW.

7.Termini ta 'Ħlas: Trasferiment tal-Wajer (T/T), L/C Irrevokabbli fil-Vista eċċ.

8.Kwantità Minima ta 'Ordni: 1Ton jew 100Pcs.

9.Garanzija tal-Kwalità: Ċertifikat EN10204 3.1, Ċertifikat tal-Mitħna, Spezzjoni ta 'Parti Terza, Servizz ta' Sostituzzjoni Ħieles.

10.Sib Aktar Rekwiżiti Fis-Suq tal-Flanges.

| BRITANNIKA BS 10 SPEĊIFIKAZZJONI TAL-FLANGE TABLE D | ||||||||||||||

| DAQS NB | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | TOQOB | |

| IN | mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 4.8 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 4.8 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 4.8 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1 ¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 6.4 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 6.4 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 7.9 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 7.9 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 9.7 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 9.7 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 9.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 12.7 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 12.7 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 12.7 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 16.0 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 19.1 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 22.2 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 22.2 | - | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 25.4 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 28.6 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 31.8 | - | - | 616.0 | - | - | - | - | 16 |